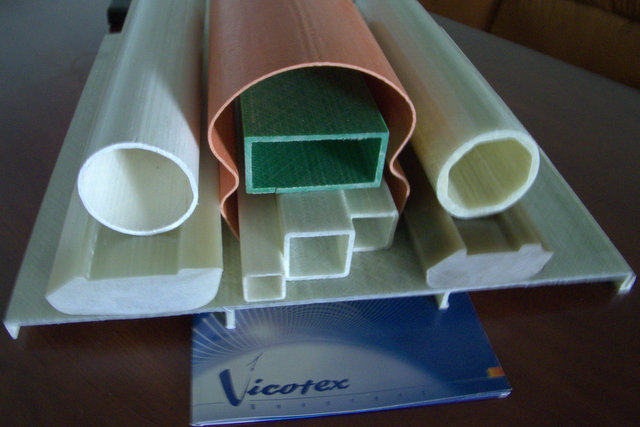

The pipe sections (30x30, 40x40, 50x50, 50x100, D80)

Pultruded composite profiles have a number of significant advantages over metal counterparts. The main ones are:

• Low weight, easy to create designs;

• High strength characteristics;

• Easy to assemble virtually any configuration decisions;

• Immunity to the effects of temperature, sunlight, moisture and other atmospheric phenomena.

• Corrosion resistance;

• Good dielectric properties;

• Electromagnetic transparency;

• Low thermal conductivity;

• Aesthetic appearance.

Composite profiles are easy to process: they can be milled, drilled, cut, grind, and interconnect with adhesive, rivets, bolts.

Due to the high fiber content (75%) profiles performed using the pultrusion have exceptional mechanical strength, which allows them to produce durable designs of any complexity.

| A(mm) | B(mm) | C(mm) | D(mm) | Weight of 1 m (kg) | Cost of 1m (€) |

|---|---|---|---|---|---|

| 30 | 30 | 2,5 | 2,5 | 0,60 | 2,5 |

| 40 | 40 | 4 | 4 | 1,30 | 5,3 |

| 50 | 50 | 4 | 4 | 1,60 | 6,6 |

| A(mm) | B(mm) | C(mm) | Weight of 1 m (kg) | Cost of 1m (€) |

|---|---|---|---|---|

| 80 | 76 | 4 | 1,80 | 8,2 |

| A(mm) | B(mm) | C(mm) | D(mm) | Weight of 1 m (kg) | Cost of 1m (€) |

|---|---|---|---|---|---|

| 100 | 50 | 4 | 4 | 2,30 | 10,3 |

Use for construction purposes structures of composite profiles can successfully solve many problems, from the individual building to the erection of large industrial facilities and road infrastructure.

Tel/fax:

Tel/fax: E-mail:

E-mail: